Modernisation

6 reasons for retrofitting an existing machine

Re-establishment of production security

Retrofitting increases the production security, because:

- up-to-date documentation simplifies troubleshooting,

- high availability of spare parts enables short downtimes,

- the user interface is simple and efficient to use,

- the amount of connectors are reduced, thus avoiding points of failure.

Quick execution

Refurbishing can be completed in four to twelve weeks. This is made possible by:

- standardising the components, thus simplifying the planning phase,

- being able to complete procurement before stopping production on the machine,

- pre-assembling parts to shorten the installation time.

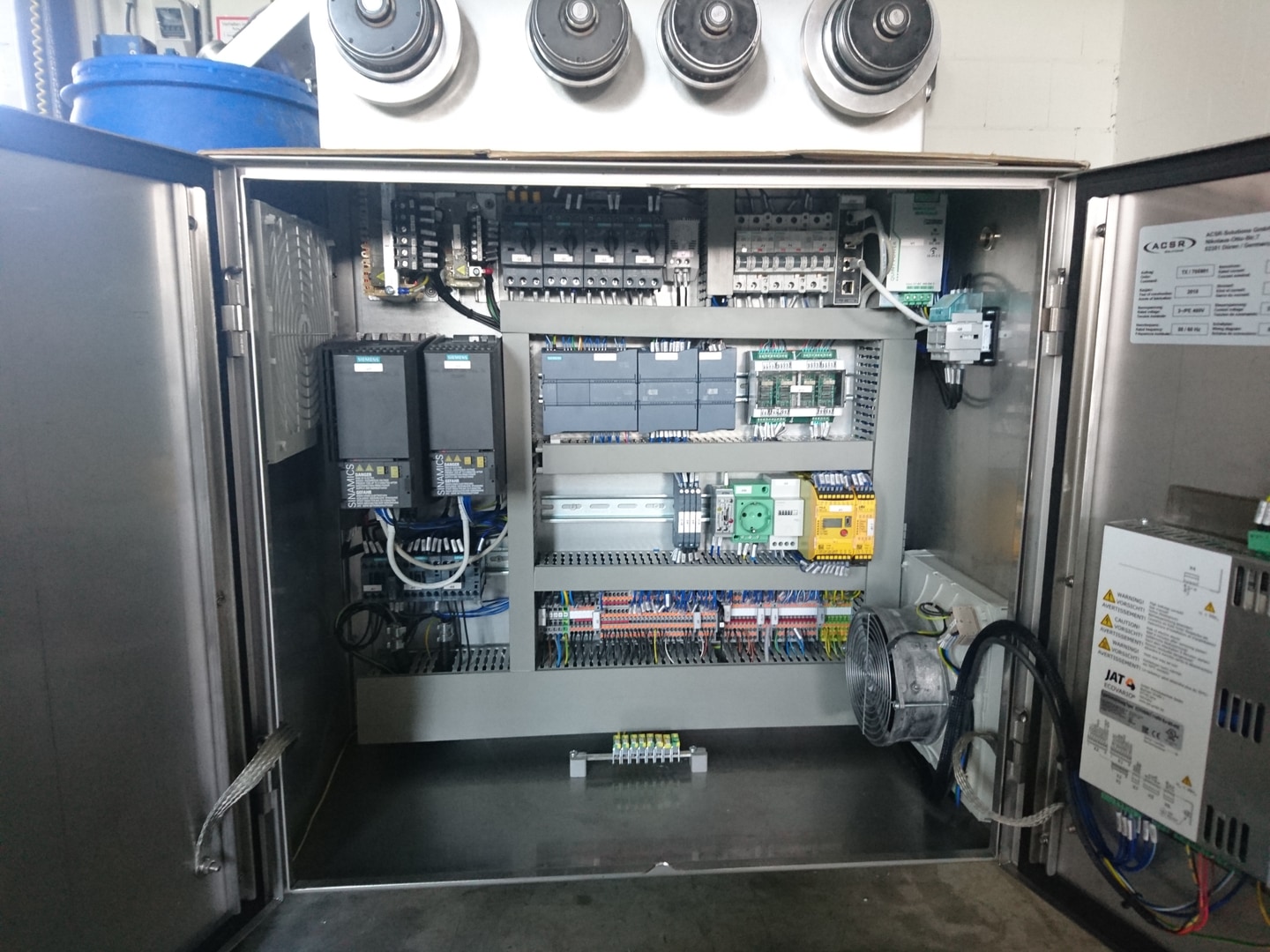

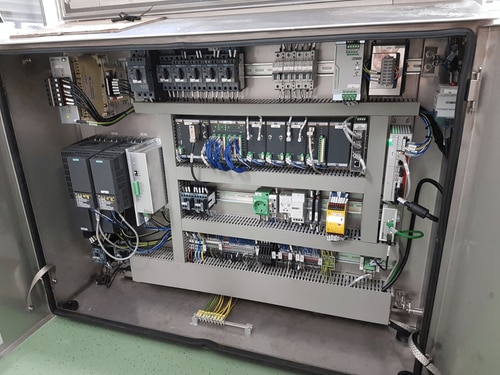

Industry 4.0 ready

The automation of the machine is returned to state-of-the-art through the modernisation, enabling

- the machine to be integrated into the network, making all network resources, like printers and shared drives, available to it,

- remote maintenance,

- integration into the operational data collection,

- future extensions for more functionality, such as state monitoring for predictive maintenance.

Highly economical

Modernising is more economical, as compared to purchasing a new machine, because:

- only defective, worn and unavailable parts are replaced, not the entire machine,

- the machines capabilities are known, ensuring all products can be manufactured,

- format parts can continue to be used,

- complex re-validation of the machine is not necessary.

Doubling the running time

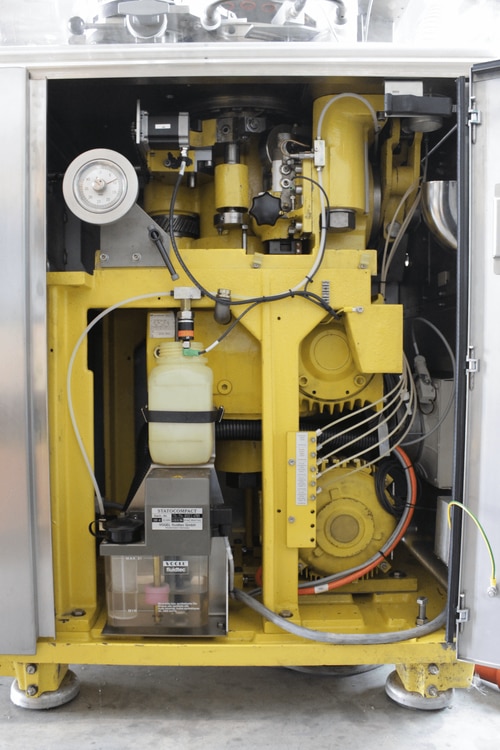

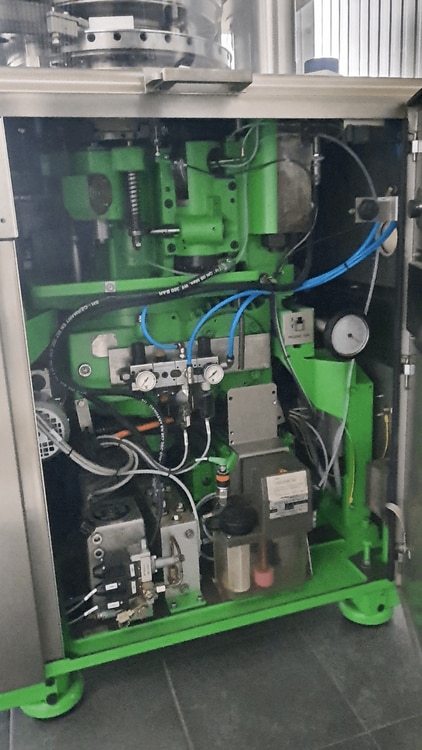

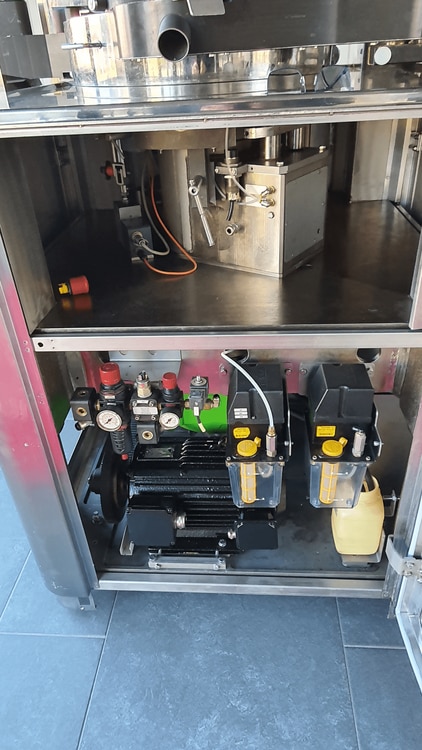

After modernising, the machine returns to new condition. We achieve this by retrofitting or replacing

- the transmission and the rotor shaft,

- the punch-carrying parts and the rotor,

- the wearing parts, like bearings, the seals and the lubrication lines,

- the entire electrical system,

- the process technology,

thus returning the machine to the state of the art, for example in regards of CE-Conformity and production guidelines

Ecological

Modernising an existing machine is more ecological than buying a new one is more ecological, because:

- it at least doubles the lifetime,

- energy-consumption is reduced by using new, energy efficient drives,

- less resources are used, since, for example, no new steel is needed to manufacture the machine frame,

- modern components enable a higher efficiency,

- technologies for predictive maintenance are enabled.